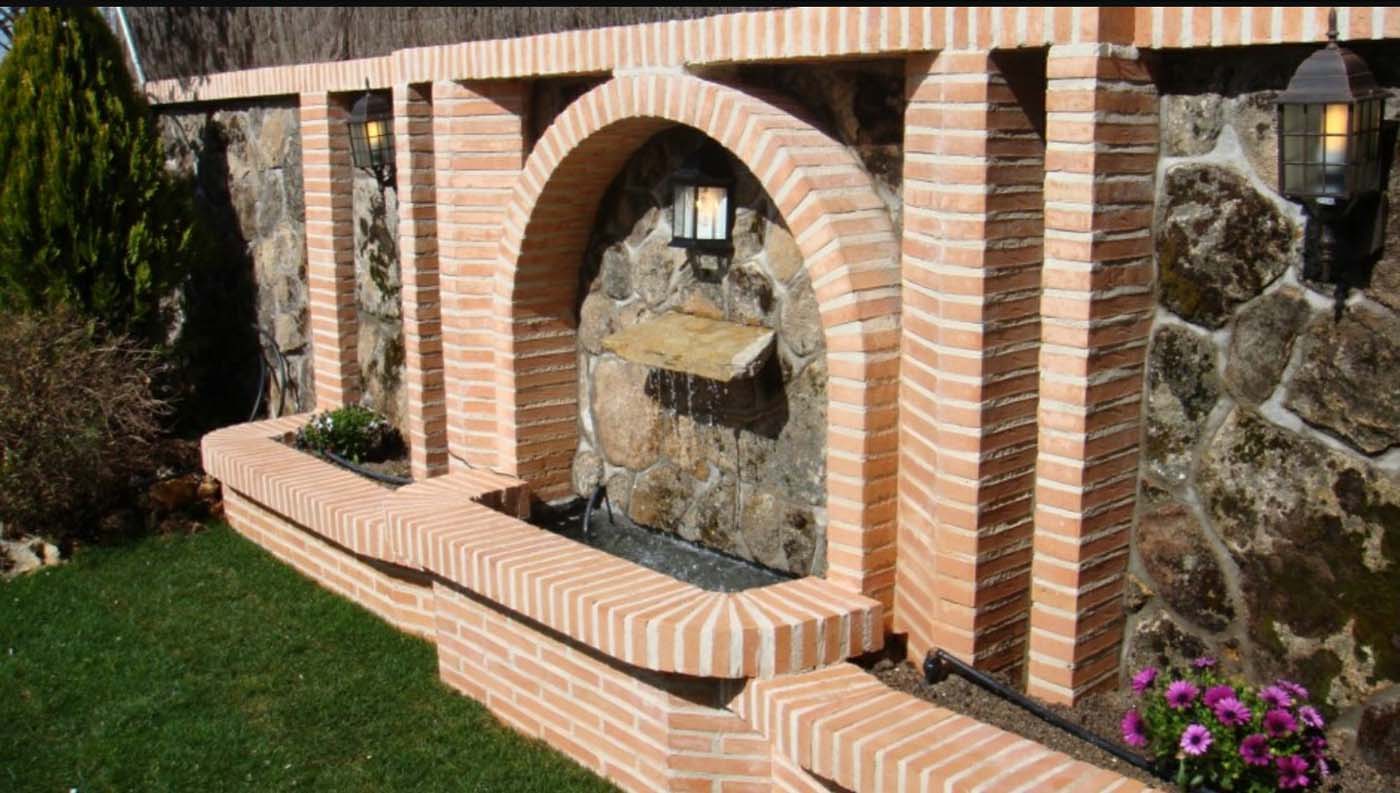

Rustic manual bricks

Rustic 100% handmade terracotta bricks.

One-of-a-kind pieces

Our rustic handmade bricks, also known as handmade bricks, Arabic bricks, Castilian bricks, rustic traditional bricks, Toledo bricks, face bricks or rustic pilasters are 100% handmade one by one.

Each piece is one of a kind and made by hand the traditional way. Each piece features an irregular finish that makes it completely original and exclusive. Each piece features an irregular finish that makes it completely original and exclusive.

They have a red base colour with shades ranging from darker to lighter hues, and they are also available in pink, straw and tan brown. The burn marks from flames in the kiln inherent to the traditional firing process are found on each brick.

They are also called “stacked” bricks as they were stacked before they were baked in kilns.

They are widely used in the refurbishment of buildings and monuments, as they have been used for centuries in popular and traditional architecture.

Indoor and outdoor use

They can be used on both interior and exterior façades without cladding. This brick adds character and tradition to any building. This brick adds character and tradition to any building.

Customisation

It is possible to order bricks in custom sizes.

Sizes

Rustic brick |

Rustic half brick 3.5cm |

Rustic brick |

Rustic brick 17 × 35 |

Brick 8 × 35 |

|

| Sizes cm | 25,5 x 12 x 3,5 | 25,5 x 6 x 3,5 | 27 x 13,5 x 4,7 | 35 x 17 x 3,5 | 35 x 8 x 3,5 |

| Pcs./pallet | 830 | 1660 | 650 | 450 | 900 |

| Minimum weight | 1,7 kgs | 0,9 kgs | 3 kgs | 3,5 kgs | 1,75 kgs |

| Normalised strength | 24N/mm² | 20N/mm² | 20N/mm² | 21N/mm² | 21N/mm² |

| Uds/m² | 74 un/m² | 74 un/m² | 56 un/m² | 55 un/m² | 55 un/m² |

| m²/palet | 11,2 | 22,4 | 11,6 | 8,1 | 16,3 |

| Pallet weight | 1.400kg | 1.500kg | 1.950kg | 1.575kg | 1.575kg |

*Sizes may slightly vary as the products are made by hand. This is likewise true for the number of pieces per pallet as they are stacked one by one.

** Pcs./m² calculated with a 1.5cm mortar joint/perpend

100% handmade

The brickmaking process is completely manual, according to a traditional method dating back to Roman times. It is a completely artisan process.

Water is added to clay powder and kneaded to make clay. The clay is then shaped in a mould to get the desired shapes and sizes. The first stage of the drying process is done naturally while the second stage involves baking in a kiln to produce the final products.

Request information

GET A QUOTE

Are you interested in our products?

Get a no-obligation quote.